Products

Production lines & supporting equipment

Tortilla Production Lines

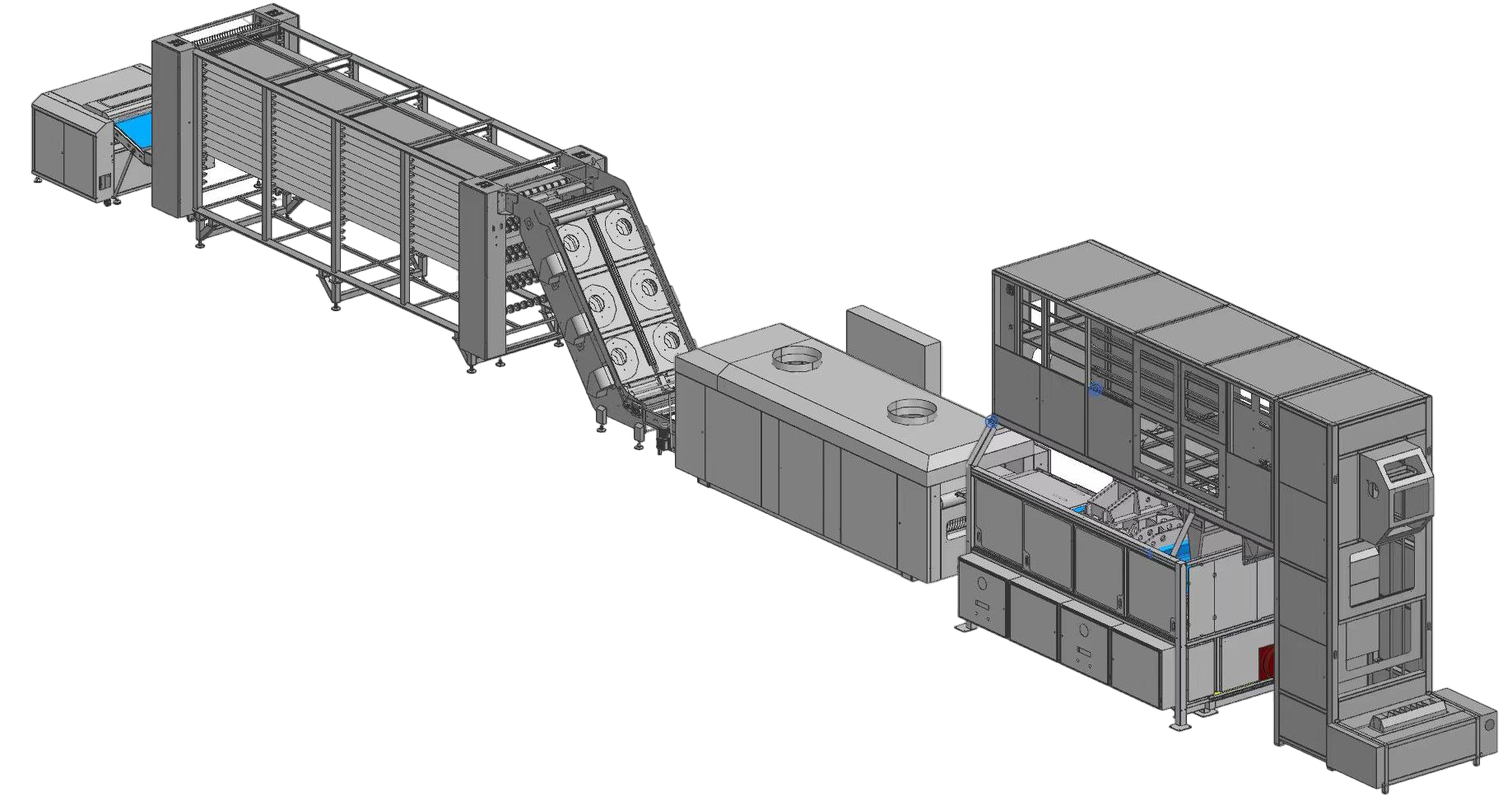

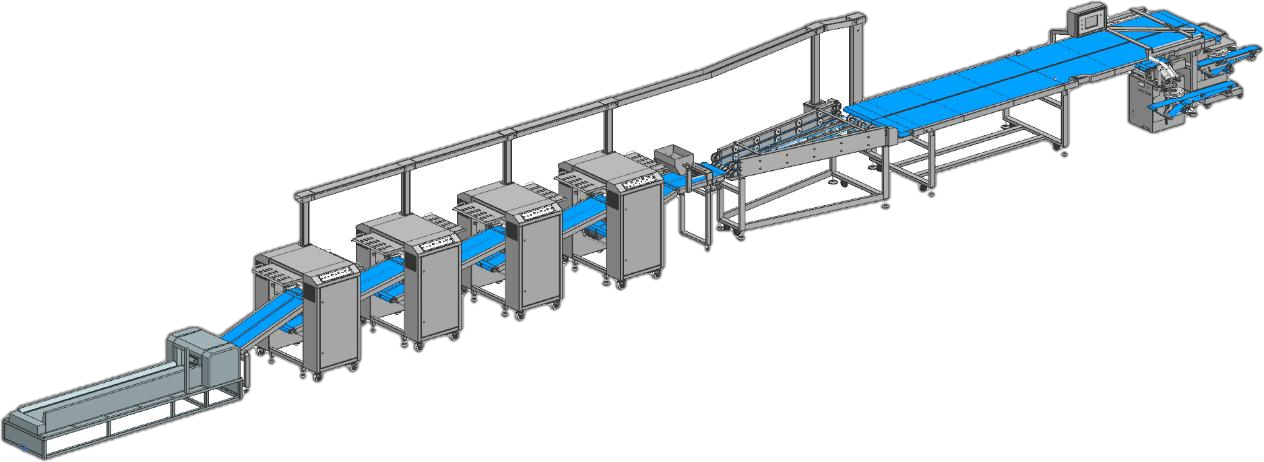

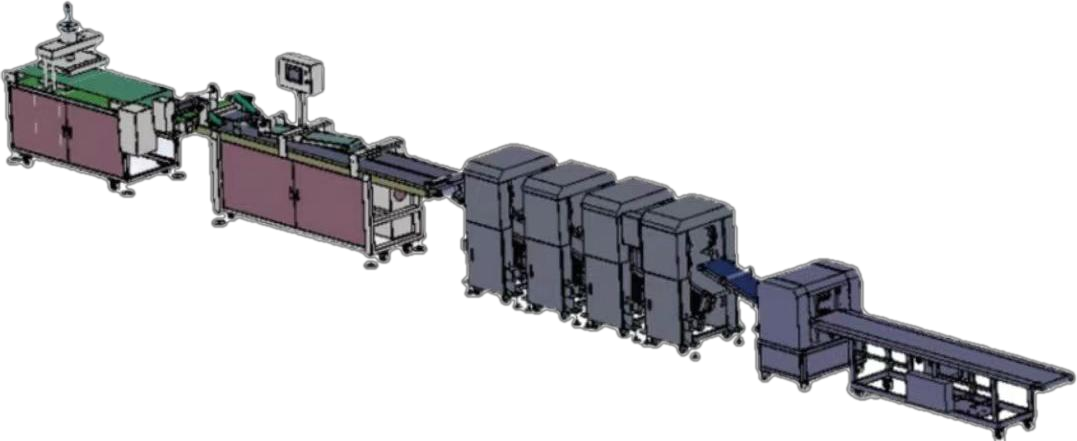

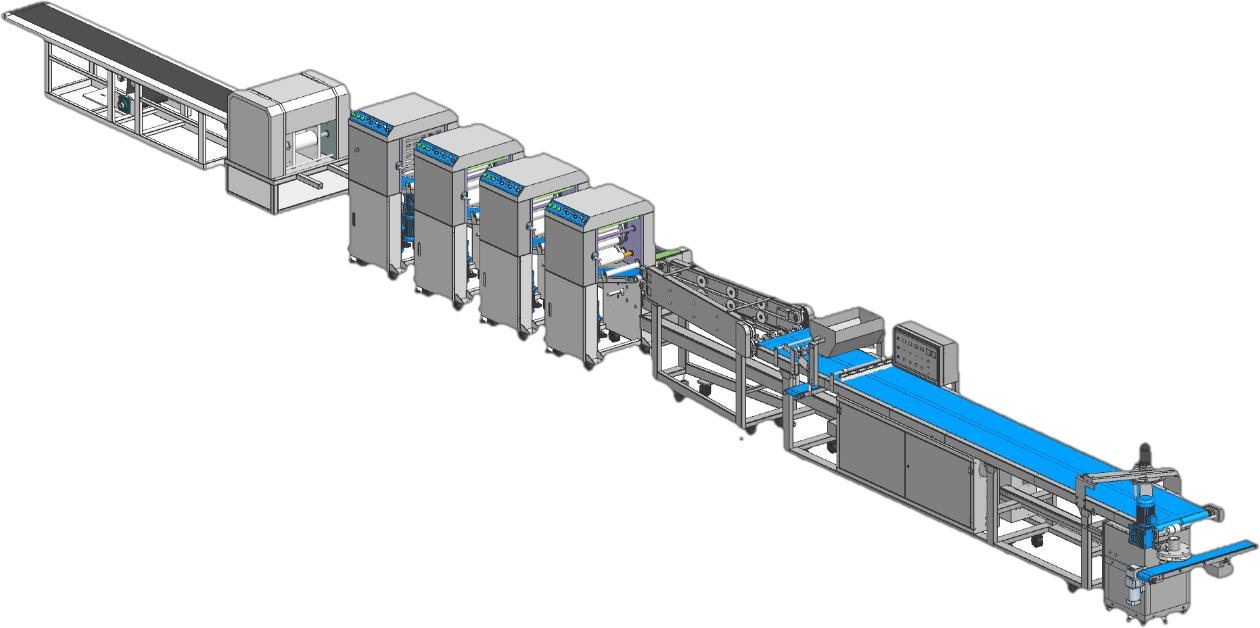

JKXGB-1200 Super Tortilla Automatic Production Line

High-yield, high automation tortilla line with continuous pressing workflow for industrial production.

- 6 inch: 18,000–20,000 pcs/h (by configuration)

- 8 inch: 14,000–18,000 pcs/h

- 10 inch: 8,000–10,000 pcs/h

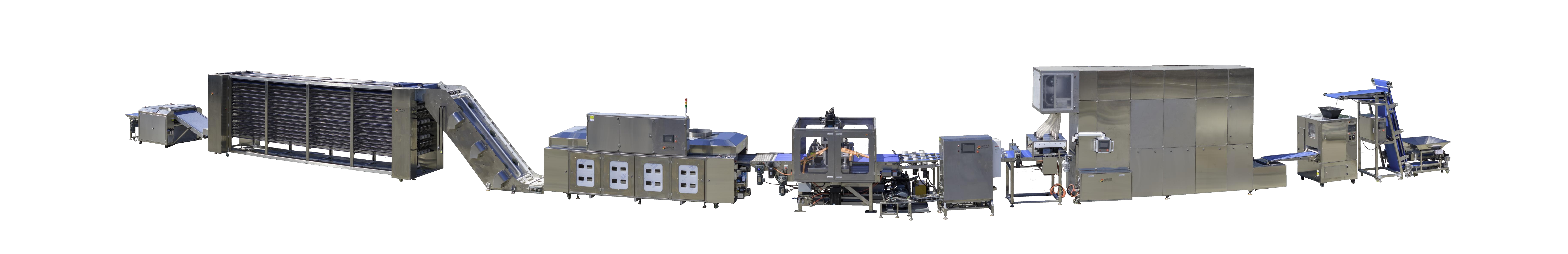

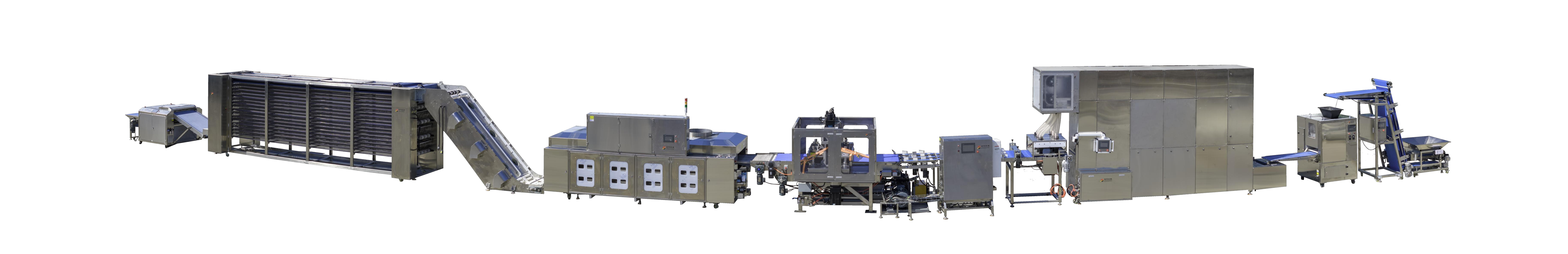

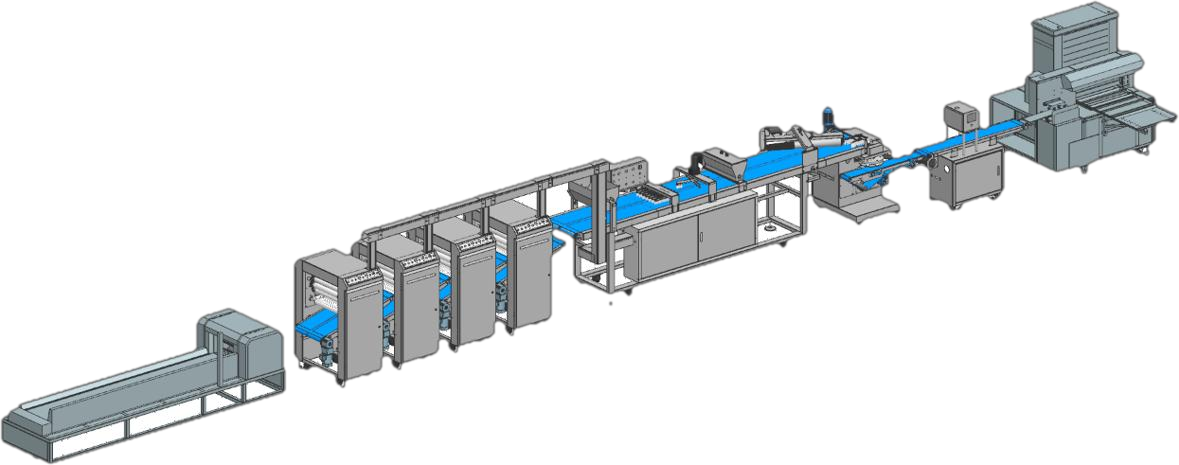

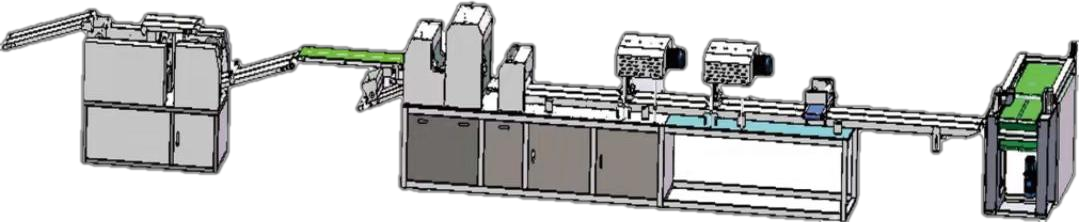

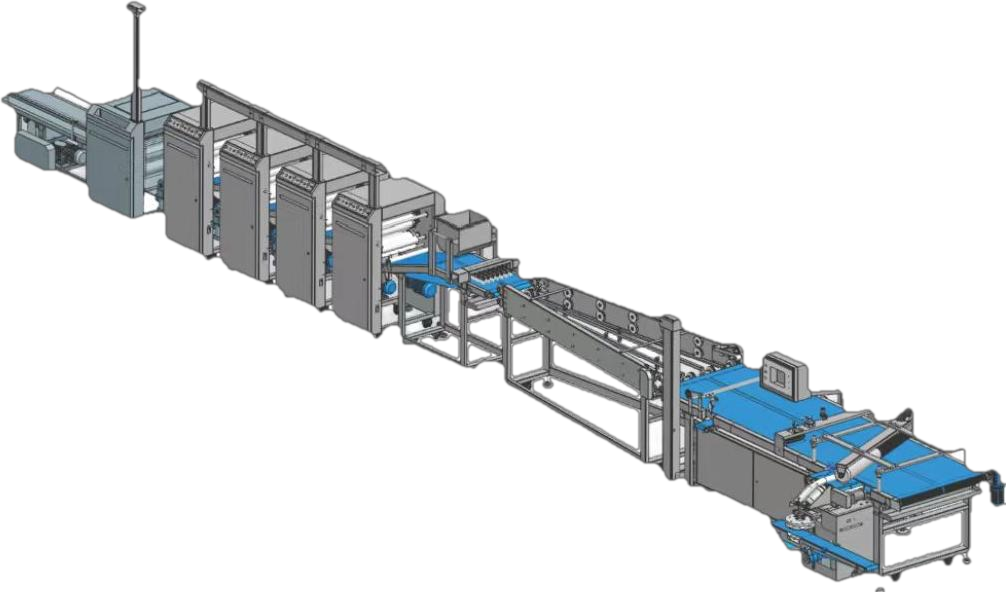

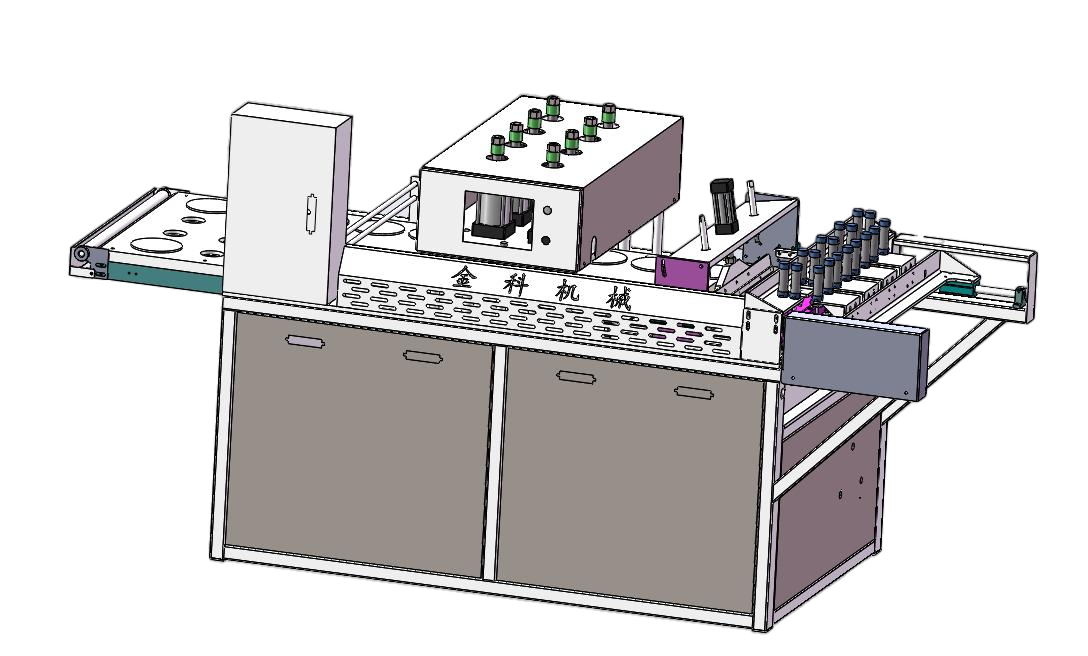

JKXGB-820 / 930 Tortilla Automatic Production Line

Automatic tortilla production line suitable for medium-to-large factories with stable output and PLC control.

- Workflow: dividing → proofing → pressing → baking → cooling → stacking

- Multiple sizes supported (by mold/configuration)

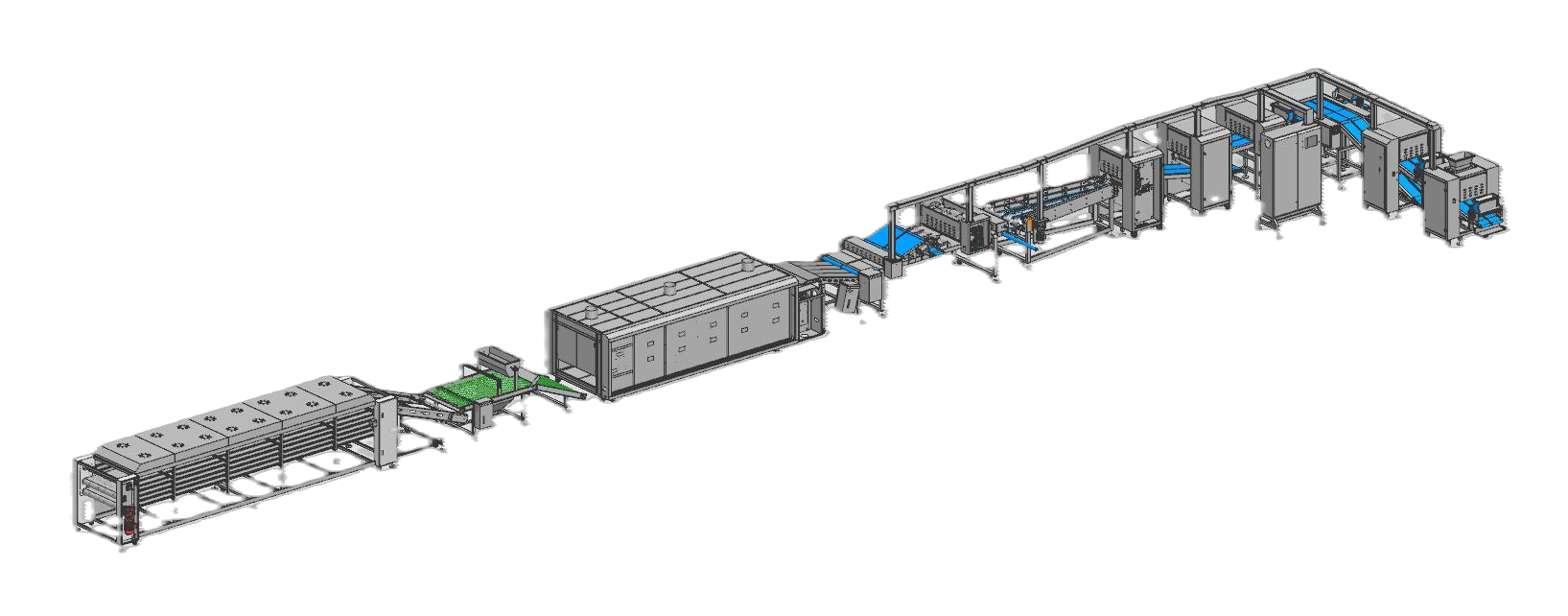

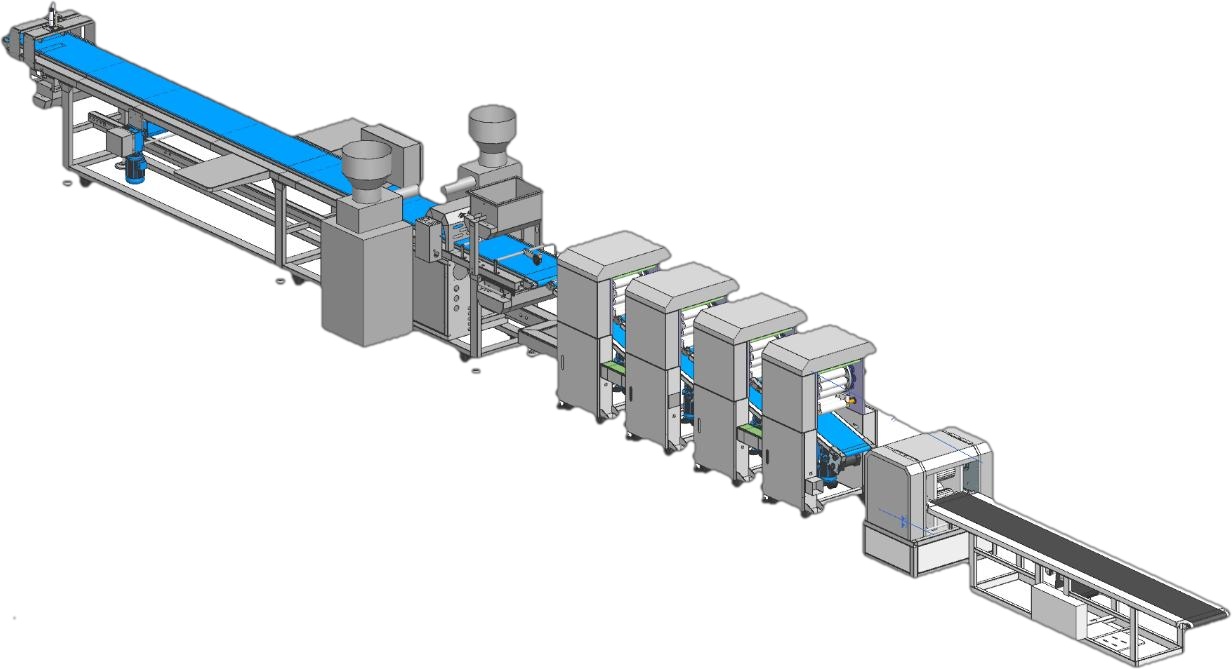

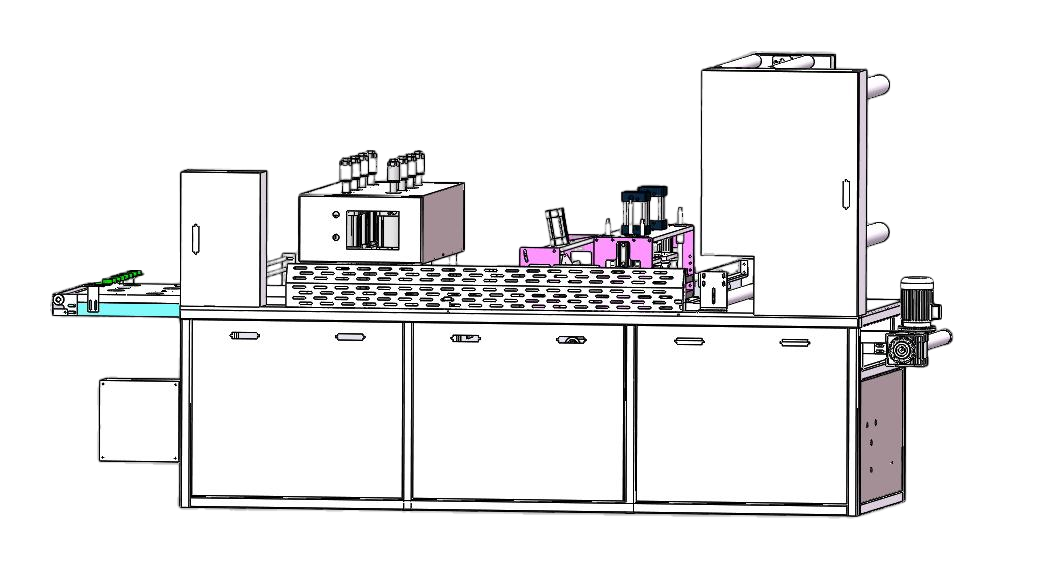

JKMXGB-650 / 720 Tortilla Automatic Production Line

Compact tortilla line for tortillas, corn tortillas, duck pancake skins and similar products.

- Cooling rack + stacking for packaging readiness

- Product scope depends on configuration

Flatbread Production Lines

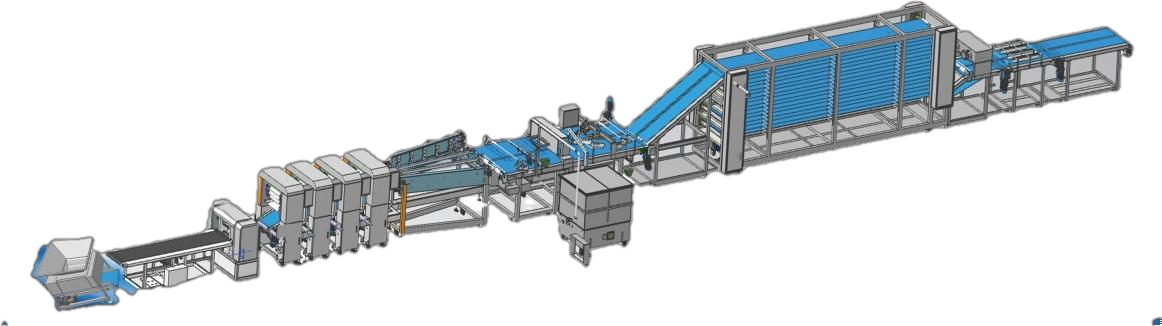

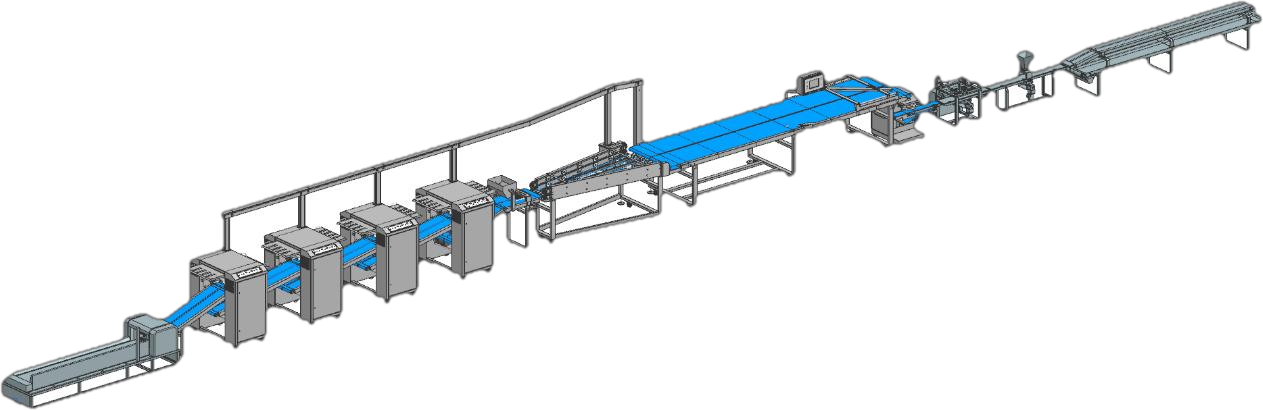

Fully Automatic Armenian Flatbread (Lavash) Production Line

Rotary baking with independent temperature zones. After baking, spraying humidifies the bread, then natural cooling and adjustable stacking.

- Temperature control: 0–300°C (zone control)

- Spray humidifying + cooling rack + adjustable stack quantity

Pie, Pastry & Specialty Production Lines

JKXB-III Automatic Pie Production Line

Automatic pie production line for stuffed pie products.

- Product weight: 70–130 g

- Factory-ready continuous workflow

JK-SZB-II Shredded Pancake / Pastry / Crusty Pancake Production Line

Automatic layered/flaky product line including thinning, widening, oil brushing, rolling and forming.

- Designed for layered texture and stable output

- Supports multiple regional pastry products

JKLRHS Automatic Donkey Burger Production Line

Automatic production line for donkey burger-style baked products.

- Production capacity: 3,600–4,000 pcs/h

- Diameter: 100–150 mm

JKZMSH Automatic Sesame Pie / Tang Huoshao Production Line

Automatic line for sesame paste pie and related baked products.

- Production capacity: 3,600–4,500 pcs/h

- Product weight: 50–150 g

JKGB Egg Pie Production Line

Automatic egg pie production line for continuous output.

- Production capacity: 2,000–4,000 pcs/h

- Power: 30 kW

Automatic Production Line for Baiji Pancake

Automatic line for Baiji pancake products with stable capacity.

- Production capacity: 6,000 pcs/h

- Diameter: 100–150 mm

Golden Beef Pie / Military Pancake / Court Beef Pie Production Line

Multi-product production line for regional beef pie and guokui-style products.

- Industrial forming workflow

- Supports multiple product variants

Xinjiang Baked Bun Production Line

High automation line reduces labor intensity and improves production efficiency.

- Automated process workflow

- Stable output and consistent shape

Ox Tongue Pastry Production Line

Production line for ox tongue pastry products with stable shaping and throughput.

- Production capacity: 3,600–4,000 pcs/h

- Factory-grade workflow

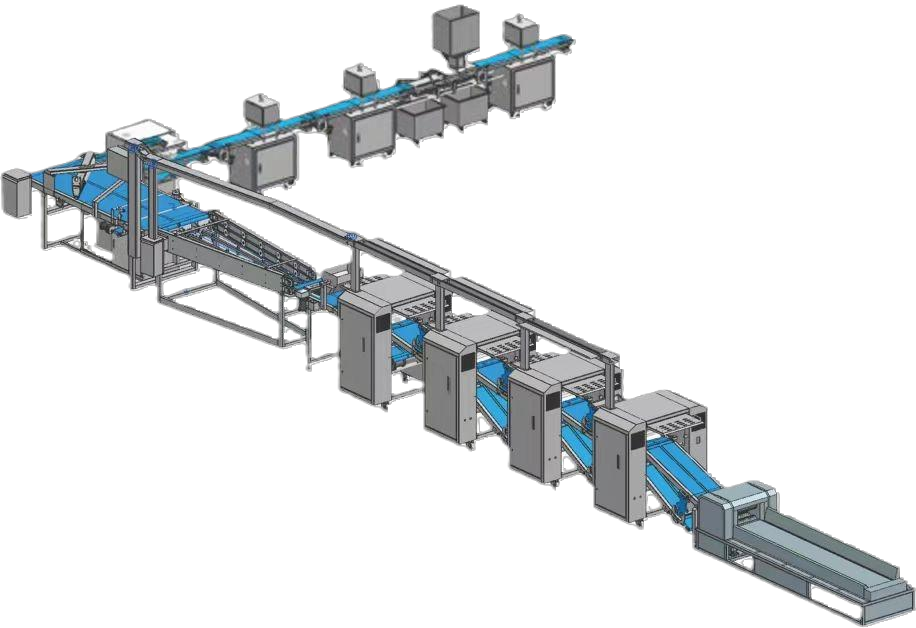

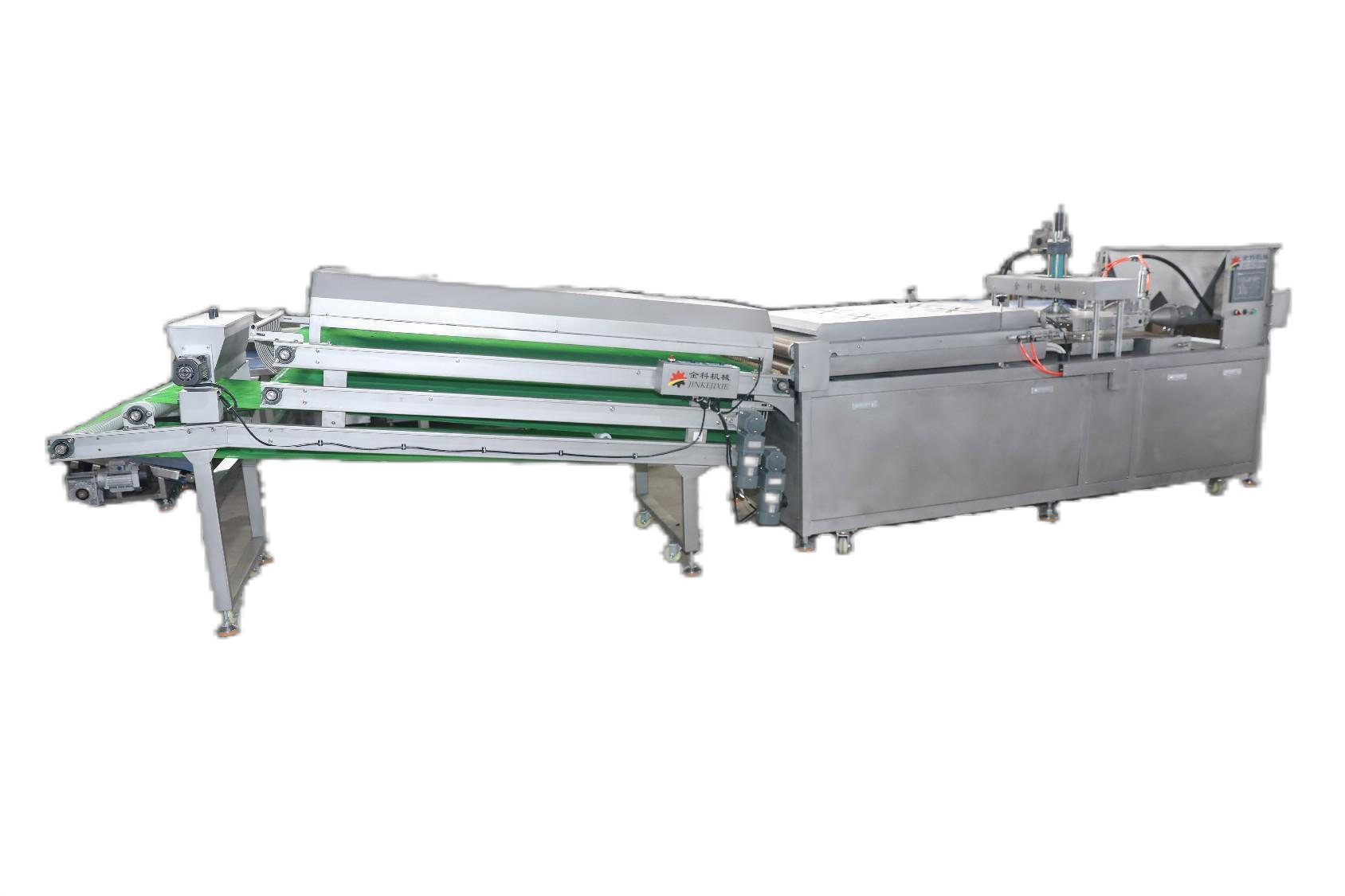

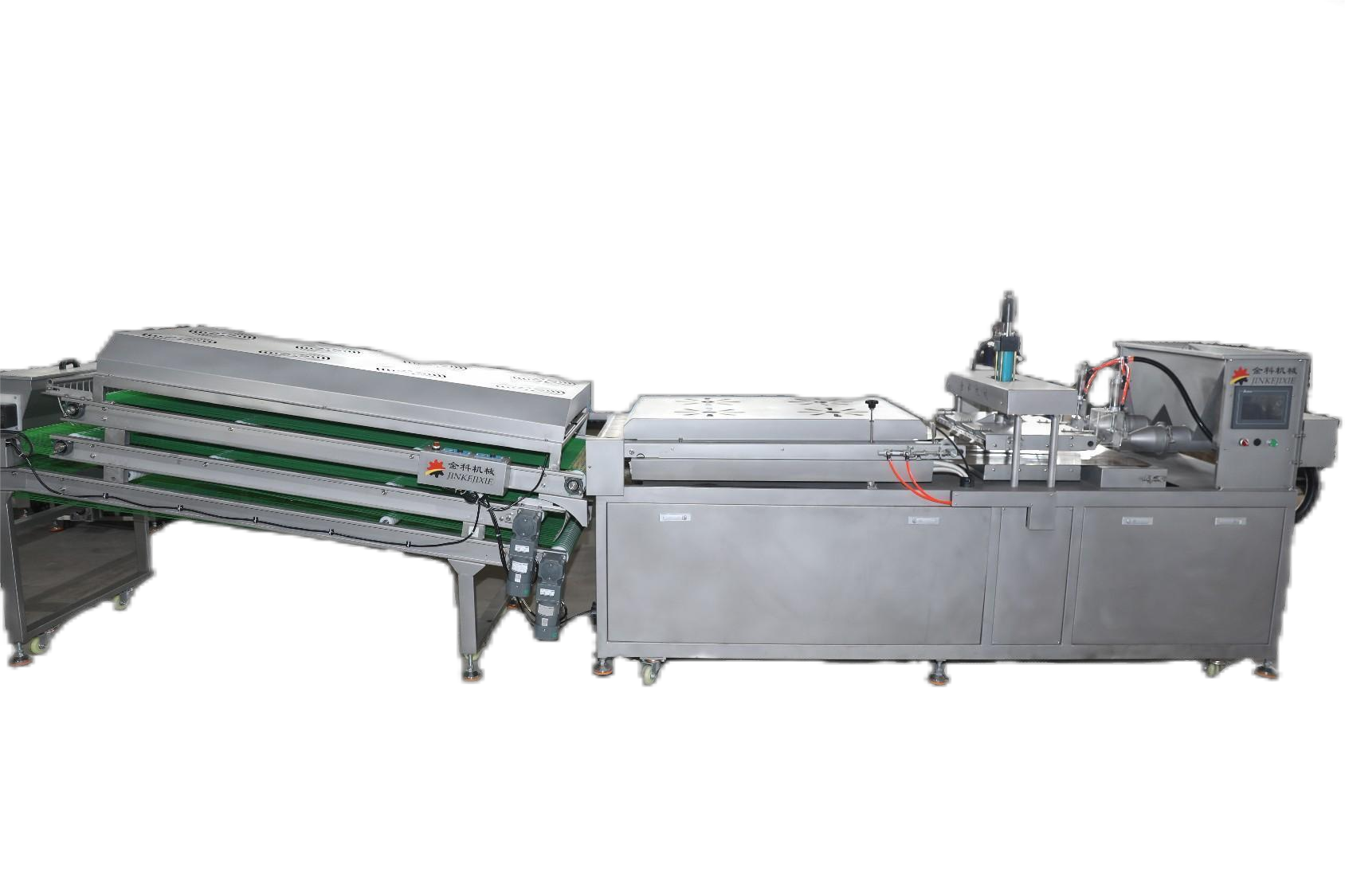

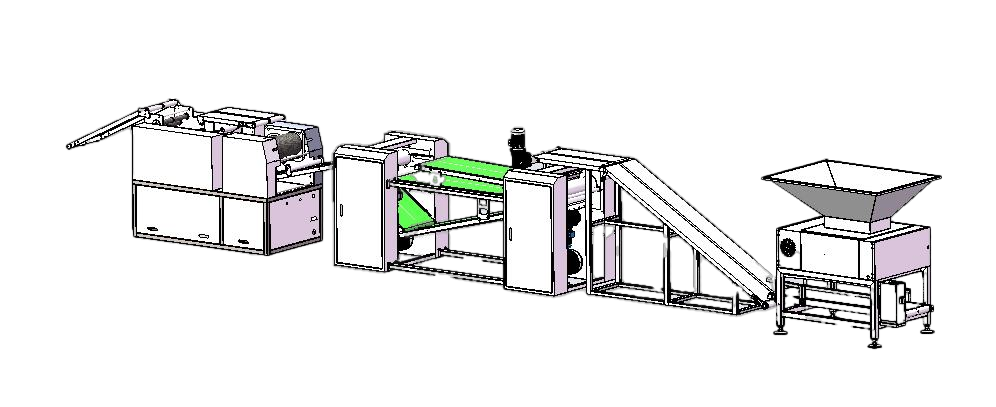

JKRJM-II Tongguan Roujiamo Automatic Production Line

Step-by-step sheeting and widening keeps gluten structure and improves handmade-like taste. Includes automatic flour feeding and oil brushing.

- Automatic feeding reduces labor cost

- Automatic oil brushing improves layering

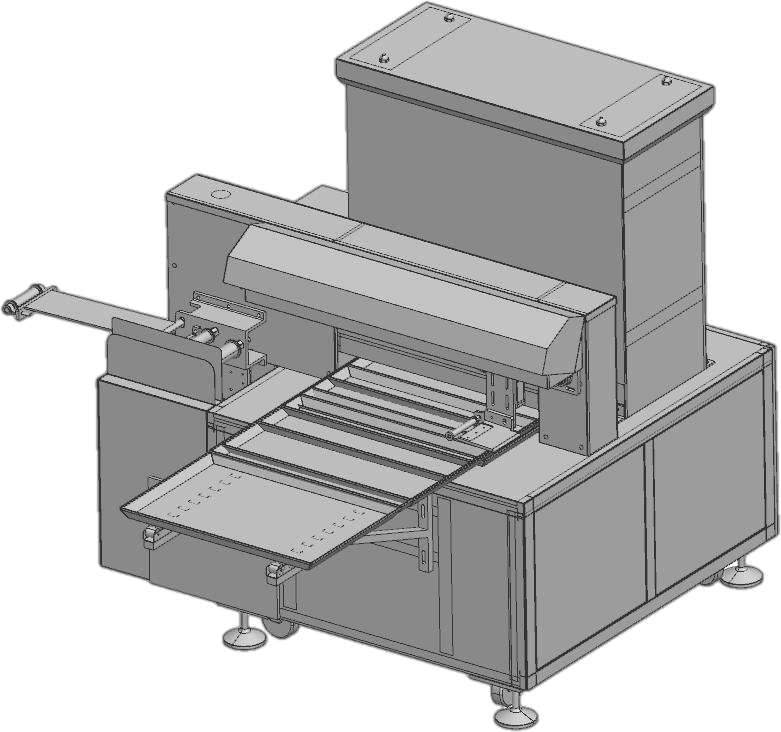

JKXBP Small Pie Crust Automatic Production Line

Suitable for duck pancake skins, flatbread skins, tortilla skins and similar products. Integrated measuring, flattening, baking and multi-layer cooling.

- Measuring → flattening → baking → multi-layer cooling

- Multiple models/configurations supported

Multi-Product Dough Lines

Doughnut / Buns / Steamed Buns / Rolls / Lotus Leaf Bun / Hollow Cake Production Line

Flexible line concept for multiple dough-based products. Adjustable shaping and cutting, stable quality and continuous output.

- Designed for product switching

- Industrial structure and stable control

Supporting Equipment & Modules

Flattening and Laminating Machine

Dough flattening and laminating module for continuous lines.

One-out-four Laminating Machine

High-efficiency multi-lane laminating equipment.

Circular Film Laminating Machine

Circular film laminating module for specific forming/pack workflows.

JK One-out-nine Proofing Line

Proofing module for dough fermentation workflow (configurable time/capacity).

Fully Automatic Dough Elevator

Automatic dough lifting/feeding equipment to reduce labor and stabilize feeding.

JK-500 / JK-550 Dough Lump Spacer

Dough dividing equipment for consistent portioning before forming lines.

JKGX-50 Separate Filling Machine

Filling module for stuffed products with stable filling output.

JKBP Arranging Machine

Arranging/placing module for downstream process and packaging workflow.

JKYM-II Press Dough Machine

Pressing/processing equipment for dough handling in industrial lines.