Food Example Image

Tortilla Production Line

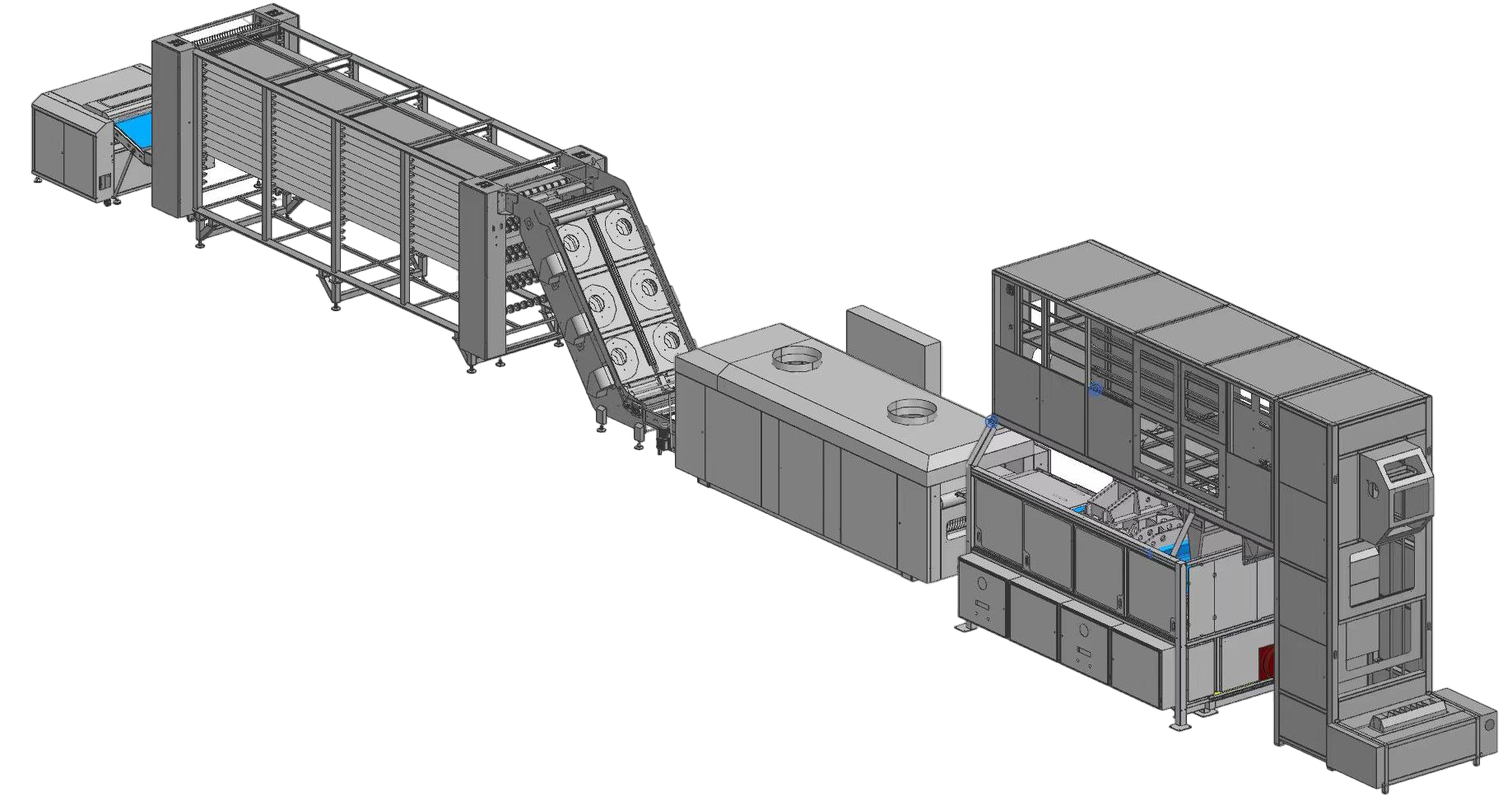

JKXGB-1200 Super Tortilla Automatic Production Line

The JKXGB-1200 is a high-yield, fully automatic tortilla production line using continuous pressing technology. It is designed for industrial-scale bakeries requiring stable throughput, consistent thickness, and reduced labor.

Automation

Up to 90%

Control

PLC + HMI (touchscreen)

Application

Flour tortillas / wraps

Line Type

Continuous pressing + tunnel baking

Technical Parameters

| Production Capacity |

6": 18,000–20,000 pcs/h 8": 14,000–18,000 pcs/h 10": 8,000–10,000 pcs/h 12": 4,000–6,000 pcs/h |

|---|---|

| Tortilla Diameter Range | 6" / 8" / 10" / 12" (by mold & configuration) |

| Thickness Control | Configurable (by pressing setting and dough formula) |

| Power | 180 kW |

| Heating | Tunnel oven (gas/electric by configuration) |

| Overall Dimensions | 40,759 × 3,300 × 4,000 mm |

| Pressure Range | 0.7–1.0 MPa |

| Automation & Safety | Sensor monitoring, safety guards, emergency stops, interlocks |

| Application | Flour tortillas, wraps and similar flatbread products |

Process Flow

- Dough mixing and resting

- Dough dividing and ball forming

- Proofing via automatic proofer

- Continuous pressing and forming into tortillas

- Continuous baking in tunnel oven

- Cooling on multi-layer cooling racks

- Automatic inspection and stacking

- Ready for packaging

Options & Customization

- Custom line layout according to factory space

- Different tortilla diameters and thickness ranges

- Integration with automatic packaging and counting systems

- Energy optimization and gas consumption control

- Cooling/stacking configuration for your packaging method

Request a Quotation

Send your target capacity, tortilla size range, and available factory space. We will propose a tailored line configuration and layout.

Contact JIN KE MACHINERY