Equipment

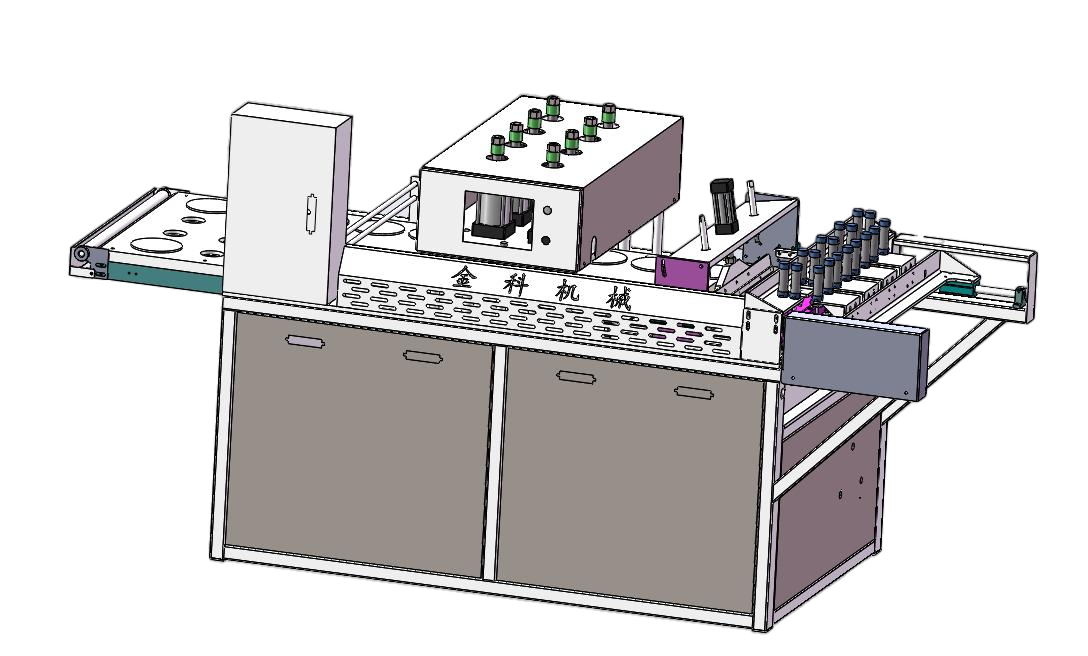

One-out-four Laminating Machine

High-efficiency multi-lane laminating equipment. Designed for increasing throughput by laminating and processing multiple lanes in parallel for industrial production lines.

Configuration

1 input → 4 lanes

Benefit

Higher throughput

Use Case

Continuous lines

Integration

Forming/cutting downstream

Technical Parameters

| Type | Multi-lane laminating module |

|---|---|

| Lane Configuration | One input split into four parallel laminating lanes |

| Typical Applications | Layered dough products, pastries and industrial forming lines |

| Control System | PLC control; lane synchronization; sensor monitoring |

| Integration | Works with upstream sheeting/feeding and downstream cutting/forming |

| Customization | Lane width, speed matching and downstream interface |

Typical Process Role

- Receive dough sheet from upstream module

- Split into four lanes and laminate in parallel

- Synchronize lane speed and thickness

- Transfer to downstream cutting/forming modules

Options & Customization

- Lane configuration matching your product width

- Speed control and synchronization options

- Safety enclosure and access design

- Integration planning for existing production lines

Request a Quotation

Tell us your required lane width, product type and target capacity. We will recommend a suitable one-out-four configuration.

Contact JIN KE MACHINERY