Food Example Images

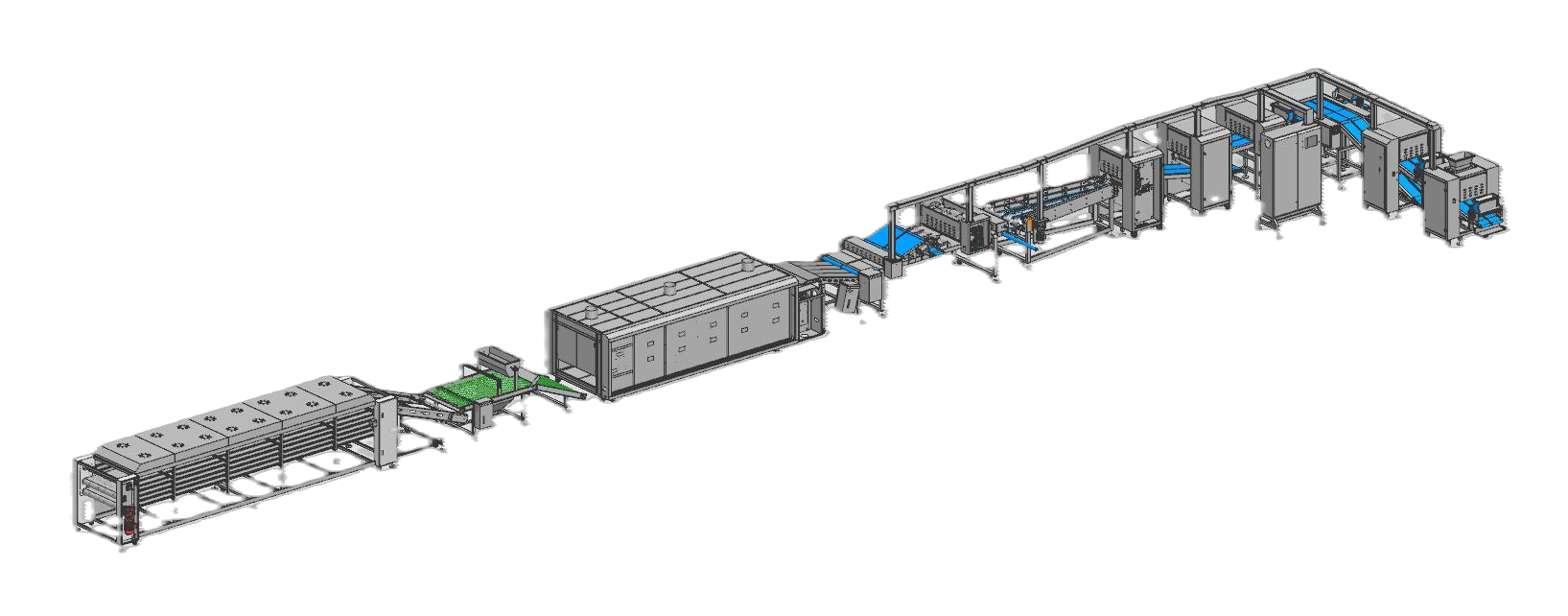

Flatbread Production Line

Fully Automatic Armenian Flatbread (Lavash) Production Line

This line is designed for continuous, high-capacity production of Armenian flatbread (lavash). It uses rotary baking with independent temperature zones, followed by spray humidifying to improve texture, then controlled cooling and adjustable stacking.

Baking

Rotary / zone control

Temp Range

0–300°C

Post-bake

Spray humidifying

Output

Cooling + adjustable stacking

Technical Parameters

| Temperature Control | 0–300°C (independent zone control) |

|---|---|

| Core Modules | Dough handling → forming → rotary baking → humidifying → cooling → stacking |

| Humidifying | Spray system after baking to improve softness and elasticity |

| Stacking | Adjustable stacking count and output format |

| Control | PLC control with stable sensors and safety protection |

| Application | Lavash / Armenian flatbread and similar thin flatbread products |

Process Flow

- Dough preparation and resting

- Continuous feeding and forming

- Rotary baking (zone temperature control)

- Spray humidifying after baking

- Cooling rack / natural cooling

- Adjustable stacking and discharge

- Packaging connection (optional)

Options & Customization

- Product size/thickness configuration based on requirements

- Customized layout according to workshop space

- Integration with packaging and counting equipment

- Energy optimization and heating system selection

Request a Quotation

Share your target product size, capacity, and factory layout. Our engineers will propose a complete lavash line solution.

Contact JIN KE MACHINERY